One of the single biggest factors in determining silage quality is cutting date. In general, Dry Matter Digestibility (DMD) will drop 10 units from the 1st of May to the 5th of June. The type of sward you have (intermediate vs. late); your geographical location; and when the ground was last grazed and fertilised are all important factors.

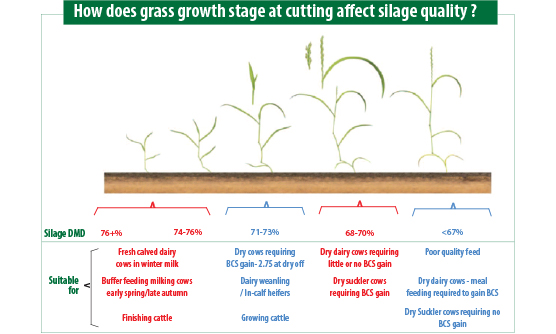

The picture below offers a guide towards what stage of the grass plant’s growth cycle will achieve a certain DMD.

Typically, to achieve silage close to 80% DMD, the grass must be cut at a similar stage of growth as you would graze.

For 75% DMD silage, the seed head can be found within the stem but will not be emerged. As the seed head appears, silage quality has turned closer to the low 70’s. Once the seed head is fully emerged, DMD has dropped below 70. Unfortunately this is the stage at which most silage in the country is cut. Leaving the crop mature any further results in a poorly preserved winter feed.

Before cutting, check back to when the fertiliser was spread and assume a usage of 2-3 units of nitrogen (N) per day. If in doubt, consult with your Local Drummonds Technical Sales Advisor and they can arrange getting the grass tested for you.

Having decided on when to cut, aim to mow during the afternoon. Grass sugars peak at 4pm and should be at least 3%.

Concentration of sugars in the grass can be increased by wilting. Tedding out and wilting for 24 hours will achieve the ideal 27 -30% DM silage. Less water means the silage clamp burns up less energy to reach a stable pH; this is why drier silage has a sweeter smell.

Wilting for more than 24 hours results in greater losses in grass degradation than the gains from increasing the DM content of the grass. If you are forced to mow on a day where no wilting is possible (still & clammy), it is better to pick up the grass right away.

Remember, the feeding quality of the grass is at its best at time of cutting, and from this point onwards, there is a continuous degradation until the clamp ceases fermentation

Fill the pit quickly; roll it well; and seal.

Silanet - Bird Protection Nets

Sizes available: 10m x 15m , 20m x 15m.

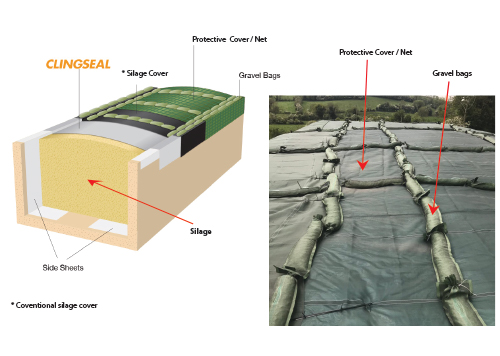

Clingseal Film

A number of our customers are using ClingSeal film for the last two years, and will now, not make silage without ClingSeal.

The principle behind the flexible vacuum sheet is exactly as the name suggests. The sheet clings to the contours of the clamp surface more closely and tucks in very well at the sides. The clinging effect helps to eliminate air pockets and forms a close fitting oxygen barrier which significantly reduces top and shoulder losses. The reduction of top and shoulder losses is very visible however the major benefit to the whole fermentation process is far greater. As there is less oxygen in the clamp, the fermentation process happens much faster and ceases sooner. Quicker fermentation results in less energy being lost fro

m the forage, leading to improved feeding value.

Sheet dimensions: 11m x 50m.

Please speak with your Your Local Drummonds Technical Sales Representative about our range of Polythene covers, Protective Netting & Gravel Bags.